The Power of Plasma Spray Coatings – Protect, Perform, Last

For industrial components exposed to extreme wear, heat, corrosion, and thermal stress, plasma spray coating provides a highly effective way to withstand high temperatures and harsh operating environments.

At Hannecard, we specialize in plasma spray ceramic coatings that enhance performance, extend component life, and reduce maintenance costs. Understanding when plasma spray is the right choice can help you protect your equipment and optimize operations.

What is Plasma Spray Coating?

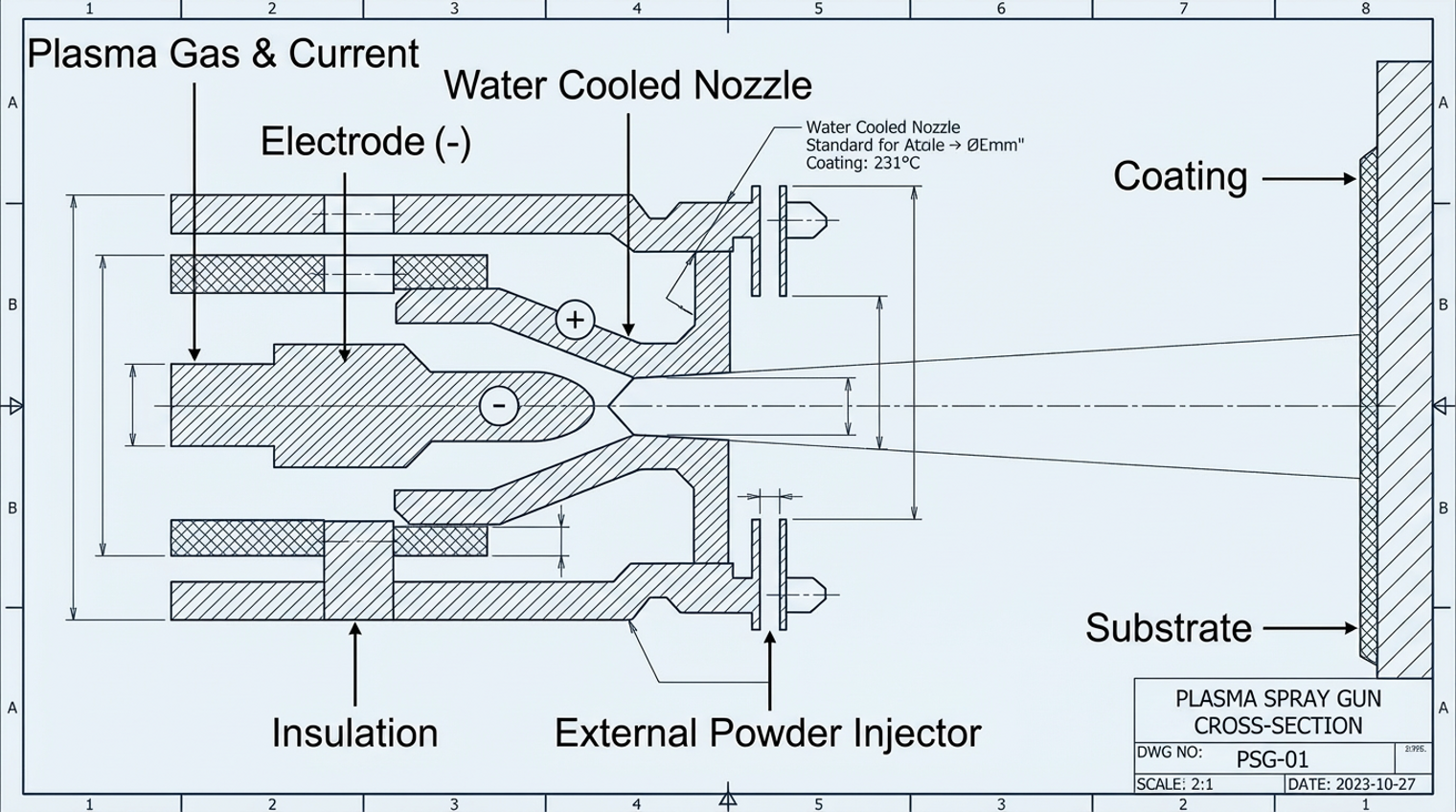

Plasma Spray Coatings is a high-temperature thermal spray process that applies powdered coating materials to a surface, creating a dense, durable layer. A plasma torch generates temperatures up to 15,000°C, melting powder materials and propelling them onto a substrate. The molten particles cool instantly, forming a strong, uniform coating.

This process is highly adaptable, suitable for both small precision parts and large industrial equipment, making it ideal across industries that demand performance and reliability.

The Plasma Spray process:

1. Surface Preparation: Components are cleaned and prepped for strong adhesion.

2. Plasma Generation: Inert gases are ionized to create a superheated plasma jet.

3. Powder Injection: Coating powders are melted in the plasma jet.

4. Deposition: Molten particles are sprayed onto the surface, solidifying into a protective coating.

The process allows precise control of thickness, density, and surface finish, ensuring consistent quality for critical components.

When to choose Plasma Spray:

Plasma spray is the right choice when components face extreme conditions or require enhanced performance:

- High Temperatures: Thermal Barrier Coating (TBC) coating system Ideal for turbines, and other ceramic composites materials for furnace components, and heat-resistant equipment.

- Heavy Wear: Ceramic coatings like chrome oxide and aluminum oxide reduce friction and extend life for rollers, shafts, and tooling.

- Corrosive Environments: Protects against chemicals, moisture, and rust in petrochemical and marine applications.

- Electrical Insulation: Provides dielectric shielding, preventing arcing and electrical damage.

- Precision Requirements: Ensures uniform, dense coatings with strong adhesion, critical for aerospace, medical, steel and high-performance applications.

Common Plasma Spray materials:

It’s high-temperature capability allows the use of ceramics and metals with high melting points. Frequently used materials at Hannecard include:

- Aluminum Oxide: Wear and dielectric resistance

- Chrome Oxide: Hardness and corrosion protection

- Zirconium Oxide / Yttria Stabilized Zirconia (YSZ): Thermal barrier and heat resistance

- MCrAlY: High Temperature bond coat

Coating thickness and multi-layer systems are tailored to each application, with specialized sealing treatments to optimize performance.

Advantages over other Thermal Spray methods:

Plasma spray offers several benefits compared to conventional thermal spray methods:

- Higher Temperature Capability: Works with materials conventional methods cannot handle.

- Superior Density and Adhesion: Creates durable, long-lasting coatings.

- Versatility: Compatible with metals, ceramics, and composites, large or small.

- Customizable Coatings: Precise control over thickness, material, and surface finish.

The result is a robust coating that enhances reliability, reduces downtime, and delivers long-term value.

Industrial Applications:

Plasma Spray Coatings are used across many industries to protect and enhance critical components such as:

- Steel & Metal Processing: Rollers, furnace components

- Power Generation: Turbines, shafts

- Petrochemical & Marine: Pumps, valves, seals

- Mechanical Engineering: Clamps, blocks

- Aerospace & Automotive: High-performance parts requiring wear or thermal protection

Hannecard’s Commitment

Every plasma coating project follows ISO-calibrated standards. Powder lot numbers are tracked, sample pieces tested, and inspections conducted at each critical step. This ensures consistent quality and reliable performance.

Get Started with Plasma Spray

For components exposed to heat, wear, corrosion, or electrical stress, plasma spray coating is a cost-effective solution. Hannecard offers customized plasma spray solutions to improve performance, extend component life, and reduce maintenance costs.

Request a quote or contact us today to explore how plasma coatings can enhance your operations.

Hannecard offers a full range of Industrial Coating and Surfacing Technologies.